Menu

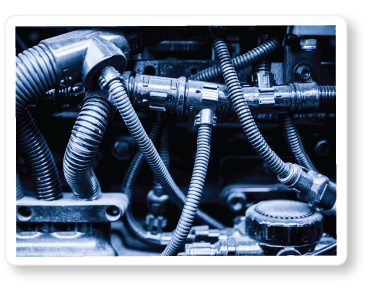

Our flexible PVC automotive wire and cable compounds find use in under-hood or cabin applications, such as primary wire, battery cable wire, brake cable wire, and trailer cable wire. We have a complete flexible PVC automotie wire product spectrum that complies with industry standards ISO 6722-1 (T1, T2 and T3), SAE J1127, SAE J1128 (GPT, HDT, SGT, TWP) and JASO D611 (AVS, AVSS, AVSSH, CIVUS).

Manner’s, Texas based, state-of-the-art plant features a highly automated flexible PVC compound manufacturing process. Coupling high intensity PVC compound mixing with both Buss and twin-screw extrusion technology, Manner Polymers is able to manufacture consistent, high-quality, custom flexible PVC compounds that are pelletized under water producing quality PVC automotive wire for the auto industry.

Manner Polymer’s automotive injection molding PVC compounds are used in electrical connectors, wire harnesses, plugs, over-mold terminators and strain relief boots. Our automotive PVC compounds meet UL 94 specification (listings include HB, V2, and V0 flame ratings) and OEM specifications, such as Ford ESB M4D317A, Chrysler MSDC 226 and GM GMP PVC 006.

Manner produces automotive PVC tubing compounds for wire harness and electrical conduit applications. Our compounds meet automotive OEM specifications (Ford ES-2U5A-IA263-AA and Ford ESB M4D-103A) and military specifications (MIL-I-631 and MIL 23053/5).

Extruded parts such as window seals, trims, moldings made using Manner’s automotive PVC compounds are served in the automotive aftermarket. Manner has existing products for these applications, but can also provide a custom PVC compound product to meet your color, gloss and physical requirements.

© 2023 Manner Polymers All Rights Reserved.